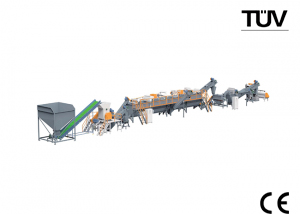

Silicone & Rubber Separation System

Our advantages:

Physical sorting, Pollution-free

Low material loss rate

High purity

Low power consumption

Flexible and customized

The Silicone & Rubber Separation System is essential in many PCR and PIR plastic recycling scenarios, such as WEEE plastic recycling, ASR/ELV plastic recycling, PVC window profile plastic recycling and many others. By taking advantage of differences in frictional coefficients, the revolutionary Silicone & Rubber Separator efficiently removes rubber, silicone, foam and other elastomers from rigid plastics.

As the industry leader in WEEE/ELV waste plastic recycling and separation, Armost has deep understanding of the plastic recycling process and key technical details in plastic recycling equipment design. As a result, we are able to continuously innovate and improve our equipment. Armost was the Winner of the Ringier Innovation Awards in 2016 and 2017. We currently hold more than 15 patents and is recognized as a National Innovation Enterprise in 2023.

—————— Our company has advanced equipment ——————

—————— Excellent technical team ——————

—————— Production technology ——————

We give prompt feedback upon receiving inquiries from customers. We will provide our customers with customized solution after evaluating the specific material state, capacity requirements, limitations and challenges at their production site etc. We believe in running an honest business and look to become long-term partners and friends with our customers by providing our best services.

Our partners think highly of us.